Working Conditions

|

General Observations on Workings Conditions |

=good working conditions | ||||

| =fair working conditions | |||||

| =bad working conditions | |||||

| Working Conditions

|

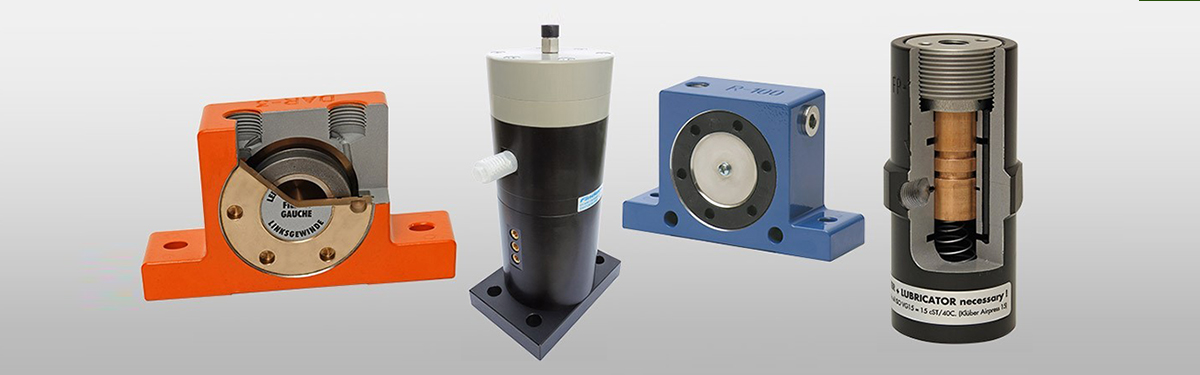

Ball Vibrators |

Roller Vibrators |

Roller Vibrators |

Useful Suggestions *Oil Quality: For the T-,DAR-and FP-Vibrator s= Hydraulic Oils as per ISO VG5 with 5 cSt/40°C for example: SHELL Tellus Oil C5 ESSO UNTO H5 BP ENERGOL HP5 MOBIL VELOCITE Oil No.4 Warning: Oil with other viscosity will reduce the frequency! |

|

| Symbol | Description | ||||

| mist lubricated compressed air |

best working conditions |

best working conditions Oil Quality=* |

best working conditions Oil Quality=* |

||

| dry, clean compressed air |

good working conditions |

good working conditions |

bad working conditions |

For T-,DAR-and FP-Vibrators use air line lubricator | |

| chean, humid compressed air | rust builds up over a long period |

rust builds up over a long period | rust builds up over a long period |

For T-and DAR-Vibrators use water separator and air line lubricator. | |

| oil contaminated compressed air |

silencer slowly clogs up, pressure build up loosens endplates |

increased friction, reduced rpm , can stop unit |

increased friction, reduced rpm, can stop unit |

Use filter | |

| dirt particles in compressed air |

as above, effect will be sooner | risk of reduced power due to blocking of inlet holes |

bad working conditions |

Use filter | |

| excessive side amplitude |

ball will go out of track and wear endplates | increases wear between rotor and endplates | increases wear between rotor and endplates | Stiffen mounting plate or bracket to reduce amplitude | |

| excessive radial amplitude |

ball will skip, wearing race | good working conditions | good working conditions | Stiffen mounting plate or bracket to reduce amplitude | |

| ambient temperature |

maximum 100 °C = 220 |

maximum 140°C = 280°F |

maximum 200°C = 400°F |

The limiting temperature ranges should be strictly observed | |

| Working Conditions |

Turbine Vibrators |

Turbine Vibrators |

Piston V ibrators |

Useful Suggestions *Oil Quality: For the T-,DAR-and FP-Vibrator s= Hydraulic Oils as per ISO VG5 with 5 cSt/40°C for example: SHELL Tellus Oil C5 ESSO UNTO H5 BP ENERGOL HP5 MOBIL VELOCITE Oil No.4 Warning: Oil with other viscosity will reduce the frequency! |

|

| Symbol | Description | ||||

| mist lubricated compressed air |

best working conditions Oil Quality=* |

best working conditions |

best working conditions Oil Quality=* |

||

| dry, clean compressed air |

bad working conditions |

best working conditions |

bad working conditions |

For T-,DAR-and FP-Vibrators use air line lubricator | |

| chean, humid compressed air | bad working conditions |

good working conditions |

good working conditions | For T-and DAR-Vibrators use water separator and air line lubricator. | |

| oil contaminated compressed air |

bad working conditions |

good working conditions |

increased friction, reduced rpm, can stop unit |

Use filter | |

| dirt particles in compressed air |

bad working conditions |

bad working conditions |

bad working conditions |

Use filter | |

| excessive side amplitude |

increases wear of bearings | increases wear of bearings | increases wear of piston |

Stiffen mounting plate or bracket to reduce amplitude | |

| excessive radial amplitude |

increases wear of bearings | increases wear of bearings |

good working conditions | Stiffen mounting plate or bracket to reduce amplitude | |

| ambient temperature |

maximum 50 °C = 120 °F |

maximum 120 °C = 250 °F |

maximum 50 °C = 120 °F Increase will reduce power |

The limiting temperature ranges should be strictly observed | |